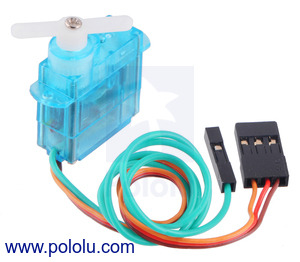

The FT1117 from FEETECH is a miniature-sized servo with the same output spline as standard servos, making it compatible with standard-sized servo horns, and the gear train is made primarily of metal gears. Servo horns and associated hardware are included.

In stock in Australia

Shipping from $4.90

+195 more from our supplier in 7-10 days

Our Code: SKU-004028

Supplier Link: [Pololu MPN:3423]

The FT1117 from FEETECH is a miniature-sized servo with the same output spline as standard servos, making it compatible with standard-sized servo horns, and the gear train is made primarily of metal gears. Servo horns and associated hardware are included. This servo can work with both 5 V and 3.3 V servo signals.

Key specs at 6 V: 0.11 sec/60°, 50 oz-in (3.5 kg-cm), 20 g.

The FT1117M is a miniature-sized servo from FEETECH with the same output spline as standard servos, making it compatible with standard-size servo horns. The pinion gear is plastic, but the rest of the gear train consists of all metal gears, allowing this servo to deliver the kind of speed and torque typically associated with larger servos.

The FT1117M works with standard RC servo pulses, offering position control over an approximate 120° operating angle for servo pulses between 900 µs to 2100 µs. As with most servos, the pulse range can be expanded to achieve an expanded operating angle, but the limits of this are not specified by FEETECH. (In our tests, we were able to get an expanded range of approximately 165° over a pulse range of 550 µs to 2400 µs, but as this is not part of FEETECH’s official specifications, it is possible different units will behave differently in this regard.)

The servo has a 7″ (18 cm) cable that is terminated with a standard JR-style connector, which is Futaba-compatible, and it includes additional servo horns and mounting hardware.

You can find more information about this servo in its datasheet (125k pdf).

For more advanced robotics applications, please note that we also carry a version of this servo that is specially modified to provide access to the feedback potentiometer through a quarter (green) wire, which lets you monitor the actual position of the servo from your controller:

|

FEETECH Mini Servo FT1117M-FB with Position Feedback. |

|---|

Note that, as with most hobby servos, stalling or back-driving this servo can damage it.

This servo is a lower-cost alternative to the 1711MG from Power HD, which has nearly identical dimensions and performance. The two servos should be generally interchangeable for most applications. The picture below shows both the FT1117M and the 1711MG side by side:

| Size: | 30 × 12 × 31.7 mm |

|---|---|

| Weight: | 20 g |

| Digital?: | N |

|---|---|

| Speed @ 6V: | 0.11 sec/60° |

| Stall torque @ 6V: | 3.5 kg·cm |

| Speed @ 4.8V: | 0.13 sec/60° |

| Stall torque @ 4.8V: | 3 kg·cm |

| Hardware included?: | Y |

| Lead length: | 7 in |

|

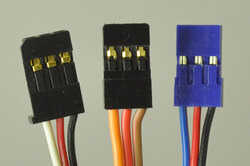

Most standard radio control (RC) servos have three wires, each a different colour. Usually, they are either black, red, and white, or they are brown, red, and orange/yellow:

Please check the specs for your servo to determine the proper power supply voltage, and please take care to plug the servo into your device in the proper orientation (plugging it in backwards could break the servo or your device).

Note: Some of the servos we carry also have an optional quarter green wire that is separate from the three standard ones. This wire provides access to the feedback potentiometer, allowing you to directly measure the position of the output. The servos with this extra wire have "with Position Feedback" at the ends of their product names. The picture below is an example of such a servo.

|

FEETECH Sub-Micro Servo FS0403-FB with Position Feedback. |

|---|

We do not specify the range of rotation of our servos because this information is not generally available from servo manufacturers. RC servos are usually intended for controlling things like the steering mechanism in an RC car or the flaps on an RC plane. Manufacturers make sure that the range is enough for these typical applications, but they do not guarantee performance over a wider range.

This means most RC servos will rotate about 90° using the standard 1–2 ms pulse range used by most RC receivers. However, if you are using a controller capable of sending a wider range of pulses, many servos can rotate through almost 180°.

You can find a servo’s limits if you use a servo controller that can send pulses outside of the standard range (such as our Maestro servo controllers). To find the limits, use the lowest possible supply voltage at which the servo moves, and gradually increase or decrease the pulse width until the servo does not move any further or you hear the servo straining. Once the limit is reached, immediately move away from it to avoid damaging the servo, and configure your controller to never go past the limit.

You might be wondering why we do not just follow the above steps for all the servos we carry and list a specification for degrees of rotation. Unfortunately, since servo manufacturers do not specify the range of rotation, it might change from one manufacturing run to the next. They will not inform us about changes that are not specified, and we have no way of knowing if or when they might change their manufacturing process.

For more information about servos and how to control them, we recommend the series of blog posts on servos starting with: Introduction to servos.