The Parallax Feedback 360° provides the functionality of a light-duty standard servo, a continuous rotation servo, a high-speed servo, and encoder feedback in one convenient package.

Special Order

Shipping from $9.90

+28 more from our supplier in 7-10 days

Our Code: SKU-004429

Supplier Link: [Pololu MPN:3432]

The Parallax Feedback 360° provides the functionality of a light-duty standard servo, a continuous rotation servo, a high-speed servo, and encoder feedback in one convenient package. Its speed is controlled with standard RC servo pulses, just like a typical continuous rotation servo, and it provides a return signal line from an internal Hall effect sensor that provides digital angular position feedback. An external microcontroller can use this signal to make the servo hold any angle, much like a standard servo except without any limits on the range of motion, or it can use it for closed-loop speed control. Recommended operating voltage range is 5.8 V to 8.4 V

Key specs at 6 V: 140 RPM (no-load), 35 oz-in (2.5 kg-cm), 41 g, CCW rotation for pulse widths above the rest point.

The Parallax Feedback 360° provides the functionality of a light-duty standard servo, a continuous rotation servo, a high-speed servo, and encoder feedback in one convenient package. Like typical continuous rotation servos, the speed of the Feedback 360° is controlled by a standard 50 Hz RC servo signal, and the speed response is nicely linear across the control signal range of 1280 µs to 1720 µs. The rest point is at 1500 µs, with a 20 µs deadband on either side. Pulse widths above the rest point result in anti-clockwise rotation, with speed increasing as the pulse width increases; pulse widths below the rest point result in clockwise rotation, with speed increasing as the pulse width decreases.

What sets this servo apart from typical other similar servos is a return signal line from an internal Hall effect sensor system that provides digital angular position feedback. Using this feedback signal, your application can make the servo to turn to and hold any angle, much like a standard servo but with an unlimited range of motion. Or, you can rotate the servo continuously at a controlled, verifiable speed as a robot drive motor. The feedback signal is a 3.3 V PWM with a fixed period of approximately 1.1 ms and a duty cycle that corresponds to the rotational position of the servo. More information about the feedback signal, including a low-level programming walkthrough with snippets of example C code, can be found in the Parallax Feedback 360° High-Speed Servo Datasheet (1MB pdf).

The recommended operating voltage range for this servo is 5.8 V to 8.4 V. At 6 V, it has a maximum rotation speed of 140 RPM (no-load), and it has a peak stall torque of 35 oz-in (2.5 kg-cm).

This robotics servo is compatible with our servo wheels for standard servos (25T, 5.8 mm spline) and Mounting Bracket for Standard-Size Servos, and it works with the control signals generated by our servo controllers, but please note that you would need a separate microcontroller to read and respond to the feedback signal if you want to use that feature. It has a 9.8″ (250 mm) lead terminated with a JR-style 3-pin servo connector, which is used to provide the servo with power, ground, and its control signal. The feedback signal is provided through a separate single wire that is terminated in a 0.1″ female connector.

This product is Parallax product ID 900-00360.

Continuous rotation servo size comparison. From left to right: SpringRC SM-S4303R, Power HD AR-3606HB, FEETECH FS5106R, Parallax Feedback 360°, Parallax (Futaba S148), and FEETECH FS90R.

| 6 V | 4.8 V | Weight (g) | Size (mm) | Direction vs pulse (1ms → 2ms) |

Digital? | Feedback? | Price | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Max speed (RPM) |

Stall torque (oz·in) |

Max speed (RPM) |

Stall torque (oz·in) |

|||||||

| SpringRC SM-S4303R | 54 | 71 | 43 | 46 | 41 | 41.3 × 20.7 × 40.2 | CW→CCW | $21.39 | ||

| SURPLUS SpringRC SM-S4303R 2-Pack | 54 | 71 | 43 | 46 | 41 | 41.3 × 20.7 × 40.2 | CCW→CW | $24.74 for a pair of servos | ||

| FEETECH FS5106R | 95 | 83 | 75 | 67 | 43 | 40.8 × 20.1 × 38.0 | CW→CCW | $24.35 | ||

| Parallax Feedback 360° | 140 | 35 | – | – | 41 | 40.0 × 20.0 × 37.2 | CW→CCW |  |

|

$29.95 |

| FEETECH FT90R | 135 | 21 | 108 | 18 | 9 | 22.9 × 12.1 × 26.5 | CW→CCW |  |

$12.63 | |

| FEETECH FS90R | 130 | 21 | 100 | 18 | 9 | 22.5 × 12.1 × 23.4 | CW→CCW | $9.82 | ||

| Size: | 40.0 × 37.2 × 20.0 mm |

|---|---|

| Weight: | 41 g |

| Digital?: | Y |

|---|---|

| Minimum operating voltage: | 5.8 V1 |

| Maximum operating voltage: | 8.4 V |

| Speed @ 6V: | 140 rpm |

| Stall torque @ 6V: | 35 oz·in |

| Lead length: | 9.8 in |

|

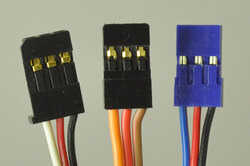

Most standard radio control (RC) servos have three wires, each a different colour. Usually, they are either black, red, and white, or they are brown, red, and orange/yellow:

Please check the specs for your servo to determine the proper power supply voltage, and please take care to plug the servo into your device in the proper orientation (plugging it in backwards could break the servo or your device).

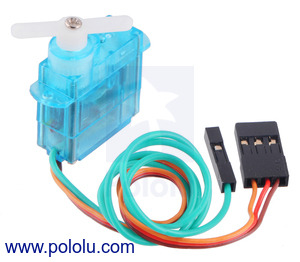

Note: Some of the servos we carry also have an optional quarter green wire that is separate from the three standard ones. This wire provides access to the feedback potentiometer, allowing you to directly measure the position of the output. The servos with this extra wire have "with Position Feedback" at the ends of their product names. The picture below is an example of such a servo.

|

FEETECH Sub-Micro Servo FS0403-FB with Position Feedback. |

|---|