This 130-size brushed DC motor has a recommended operation voltage of 3 – 12 V and is used in the larger Pololu plastic gearmotors. Approximate specifications at 6 V: free-run speed of 11,500 RPM, free-run current of 70 mA, and stall current of 800 mA.

In stock in Australia

Shipping from $4.90

+3759 more from our supplier in 7-10 days

Our Code: MEC-30066

Supplier Link: [Pololu MPN:1117]

This 130-size brushed DC motor has a recommended operation voltage of 3 – 12 V and is used in the larger Pololu plastic gearmotors. Approximate specifications at 6 V: free-run speed of 11,500 RPM, free-run current of 70 mA, and stall current of 800 mA.

This is the 130-size DC motor used in the larger Pololu plastic gearmotors (228:1 offset, 120:1 offset, 200:1 90-degree, and 120:1 90-degree). It has a recommended operating voltage of 3 – 12 V; at 6 V, the no-load speed is about 11,500 RPM, the no-load current is approximately 70 mA, and the stall current is around 800 mA. For an estimate of the torque, note that the Pololu 228:1 plastic gearmotor produces roughly 100 oz-in of torque at 6 V using this motor, and the Pololu 120:1 plastic gearmotors produce roughly 75 oz-in of torque at 6 V. The output shaft has a diameter of 2 mm.

This motor is not as electrically noisy as the FA-130 motor used in many of the Tamiya gearboxes, and it draws much less current. The two motors are the same size and have similar output power, but, with double the voltage and half the current, these units are generally more convenient to use. If you would like to use lower-current motor controllers with the Tamiya gearboxes, you can simply replace the original Tamiya motor with this and you’ll be set! (Tamiya gearboxes that work with this motor include the popular 70168 Double Gearbox and 70097 Twin-Motor Gearbox.) These motors can also be used to replace those found in the Solarbotics GM2, GM3, GM8, and GM9 gearboxes.

| Size: | 25 × 15 × 20 mm |

|---|---|

| Weight: | 18 g |

| Shaft diameter: | 2 mm |

| No-load speed @ 6V: | 11500 rpm |

|---|---|

| No-load current @ 6V: | 70 mA |

| Stall current @ 6V: | 800 mA |

This MATLAB script, written by Ali Asgher Mansoor Habiby, plots speed, power, current draw, and efficiency as they vary with torque when you input the gearmotor specifications. It also prints the resistance of the motor, and the current draw and torque at which maximum efficiency and maximum power occur.

No; the information we have available for this motor can be found on its product page. However, you can approximate various additional motor parameters from the information found in the “Specs” tab.

The electrical resistance of the motor can be approximated by dividing the rated voltage by the stall current (at the rated voltage). The electromotive force constant (Ke) can be approximated by dividing the rated voltage by the free-run speed (at the rated voltage). To approximate the motor torque constant (Kt), you can divide the stall torque by the stall current.

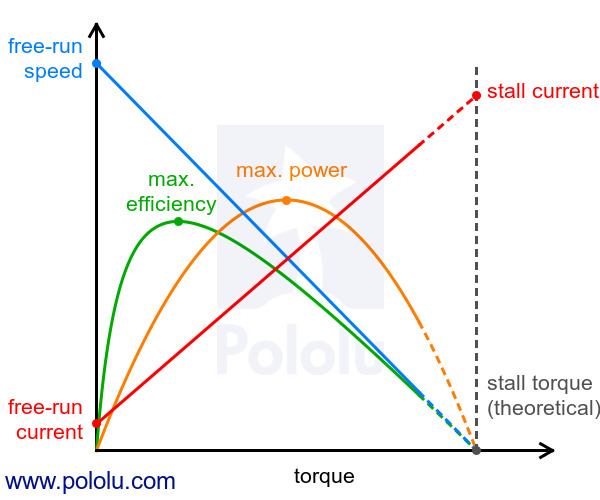

For pretty much any DC motor, the current, speed, power, and efficiency curves as a function of torque will look like those in the graph below (assuming motor voltage and temperature are constant):

|

The current and speed curves are approximately linear, and the product pages for our motors provide the approximate end points for these lines: (0 torque, no-load current) and (stall torque, stall current) for the red line, and (0 torque, no-load speed) and (stall torque, 0 speed) for the blue line.

The orange output power curve is the product of the speed and the torque, which results in an inverted parabola with its peak at 50% of the stall torque.

The green efficiency curve is the output power divided by the input power, where the input power is current times voltage. The voltage is constant, so you can divide the output power curve by the current line to get the general shape of the efficiency curve, which in turn lets you identify the torque, speed, and current that correspond to max efficiency.

There are many programs out there that you can use to generate these curves. For example, if you have access to MATLAB, you can use this customer-created MATLAB script to generate these motor plots for you from the specifications we provide for each gearmotor.

Note: A good general rule of thumb is to keep the continuous load on a DC motor from exceeding approximately 20% to 30% of the stall torque. Stalling gearmotors can greatly decrease their lifetimes, occasionally resulting in immediate damage to the gearbox or thermal damage to the motor windings or brushes. Do not expect to be able to safely operate a brushed DC gearmotor all the way to stall. The safe operating range will depend on the specifics of the gearmotor itself.