This is the motor and encoder portion of our 37D mm metal gearmotors with 64 CPR encoders. It does not include a gearbox, but the pinion gear on the output shaft works with all of our 37D mm gearmotor gearboxes, so this can be used as a replacement motor or encoder for those gearboxes.

This motor with integrated 64 CPR (counts per revolution) quadrature encoder is intended as a replacement motor and encoder for our 37D mm metal gearmotors. The 2mm output shaft has a non-removable pinion gear that works with all of our 37D mm gearmotor gearboxes. Note that we do not sell the 37D mm gearboxes separately, but if you have a gearmotor with a damaged motor or encoder (or if you want to effectively add an encoder to a version without an encoder), you can transfer the gearbox to this replacement motor.

The motor has a diameter of 34.5 mm (1.36 in) and a length of approximately 44 mm (1.7 in) from the top of the motor can to the bottom of the encoder. The top of the motor has six mounting holes evenly spaced around the outer edge threaded for M2.5 screws. These mounting holes form a regular hexagon, with the centre of each hole located 13 mm from the centre of the output shaft.. The mounting holes have a depth of approximately 3.5 mm.

You will typically want to combine this motor with a gearbox to give it a more appropriate combination of torque and speed (without a gearbox, it offers very high speed with very low torque). Our 37D mm line of metal gearmotors consist of this motor combined with different gearboxes. We do not carry the gearboxes by themselves, so unless you are looking at this as a replacement motor for a compatible gearbox you already have, we strongly recommend you consider getting a preassembled gearmotor with the gear ratio that best suits your project requirements.

| Gear Ratio | No-Load Speed @ 12 V |

Stall Torque @ 12 V |

Stall Current @ 12 V |

With Encoder |

Without Encoder |

|---|---|---|---|---|---|

| 1:1 | 11,000 RPM | 5 oz-in | 5 A | motor without gearbox | |

| 19:1 | 500 RPM | 84 oz-in | 5 A | 37Dx68L mm | 37Dx52L mm |

| 30:1 | 350 RPM | 110 oz-in | 5 A | 37Dx68L mm | 37Dx52L mm |

| 50:1 | 200 RPM | 170 oz-in | 5 A | 37Dx70L mm | 37Dx54L mm |

| 70:1 | 150 RPM | 200 oz-in | 5 A | 37Dx70L mm | 37Dx54L mm |

| 100:1 | 100 RPM | 220 oz-in | 5 A | 37Dx73L mm | 37Dx57L mm |

| 131:1 | 80 RPM | 250 oz-in | 5 A | 37Dx73L mm | 37Dx57L mm |

Note: Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

This motor is intended for use at 12 V, though in general, these kinds of motors can run at voltages above and below the nominal voltage (this motor can begin rotating at voltages as low as 1 V). Lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor.

This motor is functionally identical to the previous version we carried without end caps (it is the same motor and encoder). The black plastic end cap is easily removable if you need to access the encoder or want to slightly reduce the overall motor size, but there is a little bit of base plastic that will remain, as can be seen in the pictures below that show this motor combined with a gearbox:

A two-channel Hall effect encoder is used to sense the rotation of a magnetic disk on a rear protrusion of the motor shaft. The quadrature encoder provides a resolution of 64 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output, multiply the gear ratio by 64. The motor/encoder has six colour-coded, 11" (28 cm) leads terminated by a 1×6 female header with a 0.1″ pitch, as shown in the main product picture. This header works with standard 0.1″ male headers and our male jumper and precrimped wires. If this header is not convenient for your application, you can pull the crimped wires out of the header or cut the header off. The following table describes the wire functions:

| Colour | Function |

|---|---|

| Red | motor power (connects to one motor terminal) |

| Black | motor power (connects to the other motor terminal) |

| Green | encoder GND |

| Blue | encoder Vcc (3.5 – 20 V) |

| Yellow | encoder A output |

| White | encoder B output |

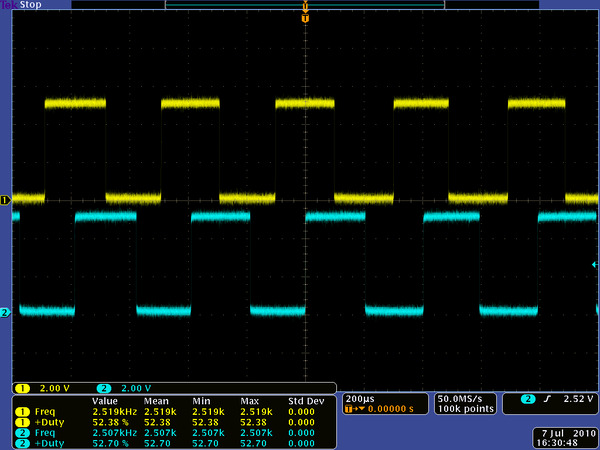

The Hall sensor requires an input voltage, Vcc, between 3.5 and 20 V and draws a maximum of 10 mA. The A and B outputs are square waves from 0 V to Vcc approximately 90° out of phase. The frequency of the transitions tells you the speed of the motor, and the order of the transitions tells you the direction. The following oscilloscope capture shows the A and B (yellow and white) encoder outputs using a motor voltage of 12 V and a Hall sensor Vcc of 5 V:

|

| Encoder A and B outputs for 37D mm metal gearmotor with 64 CPR encoder (motor running at 12 V). |

|---|

By counting both the rising and falling edges of both the A and B outputs, it is possible to get 64 counts per revolution of the motor shaft. Using just a single edge of one channel results in 16 counts per revolution of the motor shaft, so the frequency of the A output in the above oscilloscope capture is 16 times the motor rotation frequency.

We offer a wide selection of metal gearmotors that offer different combinations of speed and torque. Our metal gearmotor comparison table can help you find the motor that best meets your project’s requirements.

|

| Some of the Pololu metal gearmotors. |

|---|

| Size: | 34.5D x 46.5L mm1 |

|---|---|

| Weight: | 110 g |

| Gear ratio: | 1:12 |

|---|---|

| Free-run speed @ 6V: | 5500 rpm3 |

| Free-run current @ 6V: | 250 mA3 |

| Stall current @ 6V: | 2500 mA3 |

| Stall torque @ 6V: | 2.5 oz·in3 |

| Free-run speed @ 12V: | 11000 rpm |

| Free-run current @ 12V: | 300 mA |

| Stall current @ 12V: | 5000 mA |

| Stall torque @ 12V: | 5 oz·in |

| Lead length: | 11 in |

No; the information we have available for this motor can be found on its product page. However, you can approximate various additional motor parameters from the information found in the “Specs” tab.

The electrical resistance of the motor can be approximated by dividing the rated voltage by the stall current (at the rated voltage). The electromotive force constant (Ke) can be approximated by dividing the rated voltage by the free-run speed (at the rated voltage). To approximate the motor torque constant (Kt), you can divide the stall torque by the stall current.

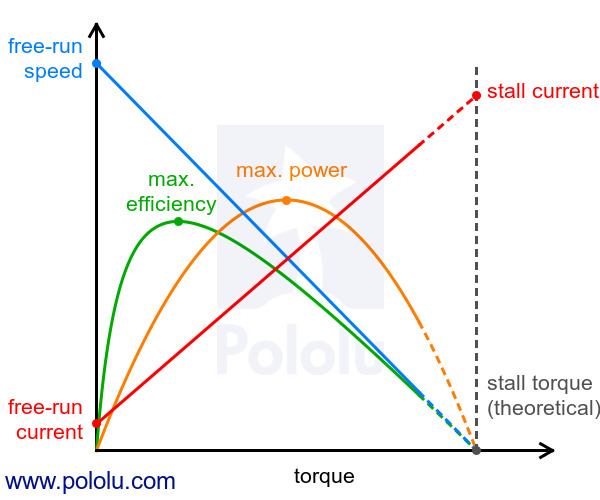

For pretty much any DC motor, the current, speed, power, and efficiency curves as a function of torque will look like those in the graph below (assuming motor voltage and temperature are constant):

|

The current and speed curves are approximately linear, and the product pages for our motors provide the approximate end points for these lines: (0 torque, no-load current) and (stall torque, stall current) for the red line, and (0 torque, no-load speed) and (stall torque, 0 speed) for the blue line.

The orange output power curve is the product of the speed and the torque, which results in an inverted parabola with its peak at 50% of the stall torque.

The green efficiency curve is the output power divided by the input power, where the input power is current times voltage. The voltage is constant, so you can divide the output power curve by the current line to get the general shape of the efficiency curve, which in turn lets you identify the torque, speed, and current that correspond to max efficiency.

There are many programs out there that you can use to generate these curves. For example, if you have access to MATLAB, you can use this customer-created MATLAB script to generate these motor plots for you from the specifications we provide for each gearmotor.

Note: A good general rule of thumb is to keep the continuous load on a DC motor from exceeding approximately 20% to 30% of the stall torque. Stalling gearmotors can greatly decrease their lifetimes, occasionally resulting in immediate damage to the gearbox or thermal damage to the motor windings or brushes. Do not expect to be able to safely operate a brushed DC gearmotor all the way to stall. The safe operating range will depend on the specifics of the gearmotor itself.