This compact, inexpensive plastic gearmotor (brushed DC motor with a 120:1 reduction gearbox) is well suited for use in small robots. While intended for operation at 4.5 V, it should run comfortably in the 3 V to 6 V range.

These brushed DC gearmotors are compact and affordable — perfect for building a quick, miniature robot. They are intended for use at 4.5 V, though in general, these kinds of motors can run at voltages above and below this nominal voltage, so they should operate comfortably in the 3 V to 6 V range (rotation can start at voltages as low as 0.5 V). Lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor. The plastic gearbox is protected by a built-in safety clutch that will typically slip before the gear teeth can shear (typically when the load exceeds around 25 oz-in, or 2 kg-cm).

The mini plastic gearmotor family offers two output shaft orientations relative to the motor shaft (offset and 90°), two motor options (normal and high-power, or HP for short), and two gearbox options (120:1 and 180:1). The 120:1 versions are white and the 180:1 versions are yellow. Additionally, some versions of these gearmotors are available with an extended motor shaft that protrudes from the rear of the motor by approximately 4.5 mm. This second shaft has a diameter of 1.5 mm and rotates at the same speed as the input to the gearbox, offering a way to add a custom-built encoder to provide motor speed or position feedback.

| Motor Type | Stall Current @ 4.5 V |

No-Load Speed @ 4.5 V |

Stall Torque @ 4.5 V |

90° output |

90° output + motor shaft |

offset output |

offset output + motor shaft |

|---|---|---|---|---|---|---|---|

| high-power (HP) |

1250 mA | 150 RPM | 25 oz-in | 120:1 mini HP | 120:1 mini HP | 120:1 mini HP | 120:1 mini HP |

| low-power | 800 mA | 120 RPM | 20 oz-in | 120:1 mini | 120:1 mini | 120:1 mini | 120:1 mini |

| 80 RPM | 30 oz-in | 180:1 mini | 180:1 mini |

Note: The stall torque values listed are approximate, and the built-in safety clutch might start slipping at lower torques.

The gearmotors in the table above all have a 3 mm diameter D-shaft output. These shafts are just like the ones on our micro metal gearmotors and are compatible with many Pololu wheels and our 3 mm universal mounting hubs. We also carry two low-power, 120:1 mini plastic gearmotors with 2 mm diameter spline outputs: 90° 2mm spline output and offset 2mm spline output. These geamotors all work with our wide and tall mounting brackets for mini plastic gearmotors.

This item has a low-power motor (800 mA stall current), a 120:1 gearbox, and a 3 mm diameter “D”-shaped output shaft that is offset from but parallel to the motor shaft. The 1.5 mm diameter motor shaft extends approximately 4.5 mm past the base of the motor.

Dimension diagram of the mini plastic gearmotor with offset 3mm D-shaft output and extended motor shaft (units are mm over [in])

This dimension diagram is also available as a downloadable pdf (78k pdf).

The 120:1 gear ratio versions have white plastic bodies and the 180:1 gear ratio versions have yellow plastic bodies (see the main product picture).

| Size: | 36.5 x 20 x 27.4 mm1 |

|---|---|

| Weight: | 19 g |

| Shaft diameter: | 3 mm2 |

| Shaft type: | offset 3mm D |

|---|---|

| Typical operating voltage: | 4.5 V |

| Gear ratio: | 120:1 |

| Free-run speed @ 4.5V: | 120 rpm |

| Free-run current @ 4.5V: | 80 mA |

| Stall current @ 4.5V: | 800 mA |

| Stall torque @ 4.5V: | 20 oz·in3 |

| Extended motor shaft?: | Y |

No; the information we have available for this motor can be found on its product page. However, you can approximate various additional motor parameters from the information found in the “Specs” tab.

The electrical resistance of the motor can be approximated by dividing the rated voltage by the stall current (at the rated voltage). The electromotive force constant (Ke) can be approximated by dividing the rated voltage by the free-run speed (at the rated voltage). To approximate the motor torque constant (Kt), you can divide the stall torque by the stall current.

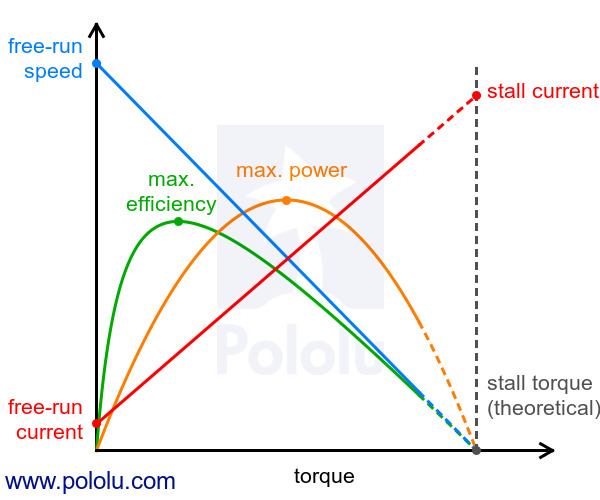

For pretty much any DC motor, the current, speed, power, and efficiency curves as a function of torque will look like those in the graph below (assuming motor voltage and temperature are constant):

|

The current and speed curves are approximately linear, and the product pages for our motors provide the approximate end points for these lines: (0 torque, no-load current) and (stall torque, stall current) for the red line, and (0 torque, no-load speed) and (stall torque, 0 speed) for the blue line.

The orange output power curve is the product of the speed and the torque, which results in an inverted parabola with its peak at 50% of the stall torque.

The green efficiency curve is the output power divided by the input power, where the input power is current times voltage. The voltage is constant, so you can divide the output power curve by the current line to get the general shape of the efficiency curve, which in turn lets you identify the torque, speed, and current that correspond to max efficiency.

There are many programs out there that you can use to generate these curves. For example, if you have access to MATLAB, you can use this customer-created MATLAB script to generate these motor plots for you from the specifications we provide for each gearmotor.

Note: A good general rule of thumb is to keep the continuous load on a DC motor from exceeding approximately 20% to 30% of the stall torque. Stalling gearmotors can greatly decrease their lifetimes, occasionally resulting in immediate damage to the gearbox or thermal damage to the motor windings or brushes. Do not expect to be able to safely operate a brushed DC gearmotor all the way to stall. The safe operating range will depend on the specifics of the gearmotor itself.